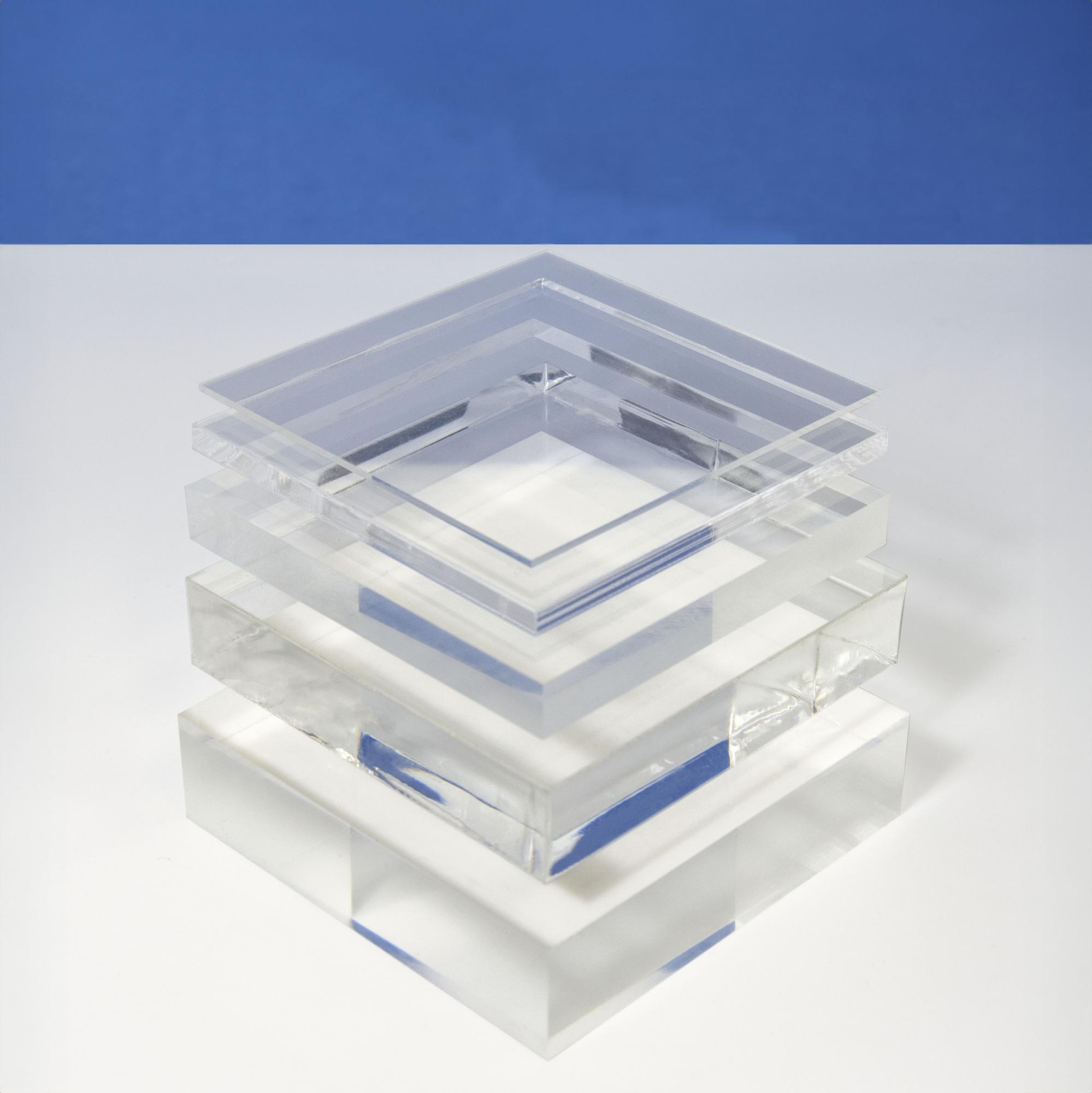

Casting or Extrusion

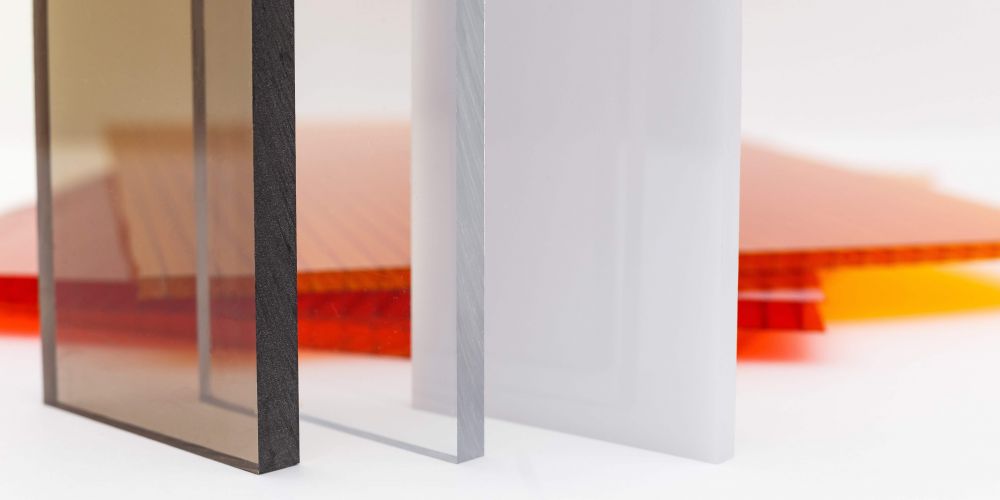

Once the polymerization is complete, the polymerized acrylic can be formed into sheets through either casting or extrusion. In the casting process, the liquid acrylic is poured into moulds to form flat sheets. This method allows for the production of thicker sheets with superior optical clarity. Cast acrylic is highly valued for its visual quality and is often used in applications where appearance is paramount, such as retail displays, high-end furniture, and decorative items.

The extrusion process involves pushing the polymerized acrylic through a die, producing continuous flat sheets. Extruded acrylic is more cost-effective and suitable for applications requiring smaller widths and thinner thicknesses, such as signage, glazing, and protective barriers.

Curing and Cooling Acrylic Sheets

After the acrylic sheets are formed, they undergo curing to solidify the material. This step involves heating the acrylic to remove any residual chemicals and achieve the desired hardness.

Curing is a critical process, as it ensures the acrylic attains its full strength and durability. Following curing, the acrylic must be carefully cooled to prevent contamination and maintain the sheets' high clarity and impact resistance.

The cooling process must be precisely controlled to avoid introducing stresses or defects that could compromise the material's performance.

Quality Control and Finishing

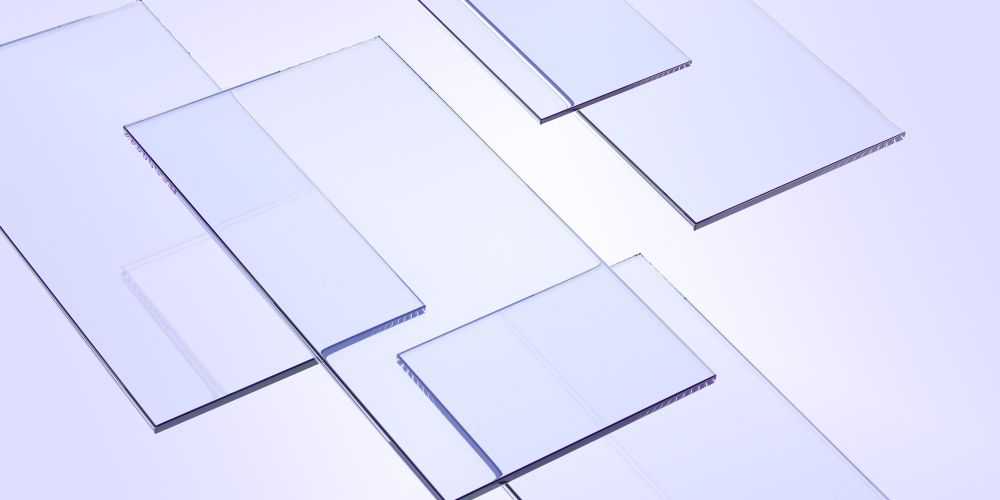

Quality control is crucial in the manufacturing process to ensure the final product meets industry standards. This includes inspecting the sheets for optical clarity, thickness uniformity, and the absence of impurities.

Advanced testing methods, such as optical inspections and mechanical testing, are used to verify that the acrylic meets the required specifications. Finishing techniques such as polishing, cutting, and laser cutting are employed to achieve the desired dimensions and surface quality.

Polishing removes surface imperfections and enhances the material's clarity, while cutting and laser cutting allow for precise shaping and customization.

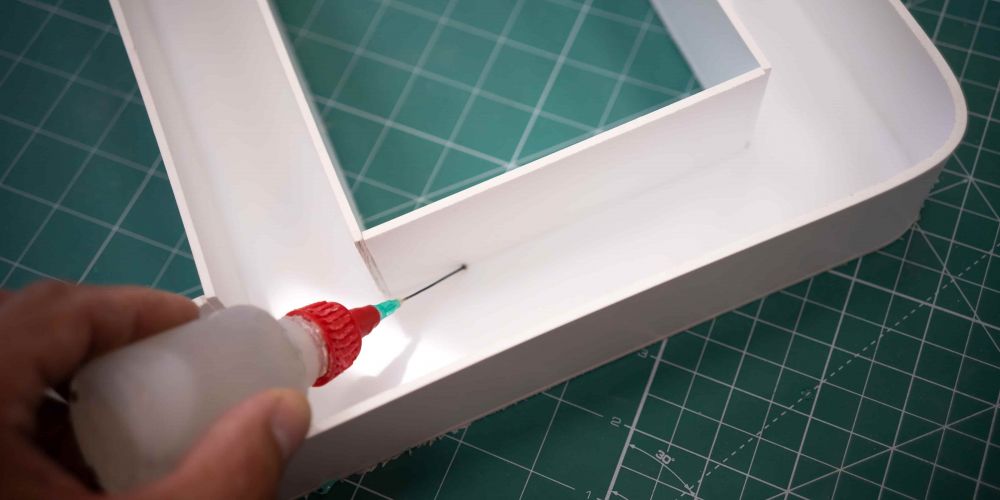

Multiple pieces of acrylic can be bonded together using specialized adhesives for more complex projects, enabling the creation of intricate designs and assemblies.