Medium-density fibreboard (MDF) is a great, versatile material for construction and decorating. While we offer many MDF varieties, choosing the right one for your task can often be overwhelming. Please note that while we have created this guide to assist you in choosing your MDF, ultimately it is your responsibility to research what material best suits your project.

This guide will take you through the different practical uses of our MDF sheets, giving you the best material for your project. For this guide, we will be primarily focussing on the differences between our standard grade MDF, moisture-resistant MDF and fire-rated MDF, though we can also provide melamine board and veneered MDF sheets if you require a material which you don’t wish to paint and will be used for visual purposes.

What is MDF?

MDF is an engineered wood product made by breaking down hardwood and softwood fibres into a fine powder, then reforming the wood fibres using wax and resin binders. The resulting panels are dense, stable and consistent.

MDF offers several advantages over natural solid wood:

- Uniform strength and density - does not contain knots or grain patterns that can weaken natural wood.

- Consistent machining - MDF does not splinter and cuts smoothly with no tearing.

- Stable when exposed to changes in temperature and humidity. This means it won’t warp or crack.

- Versatile material for painting, veneering, laminating, drilling, milling and more.

- Cost-effective and widely available.

- Range of panel sizes up to 8 x 4 feet, with thicknesses from 3mm up to 50mm.

What are the different types of MDF?

So what are the different types of MDF, and what are their uses? We've summarised some of the key areas to use each type of MDF below:

|

Standard Grade |

Moisture Resistant |

Flame Retardant |

|

|

Wall Panelling |

|

|

|

|

Bathrooms |

|

|

|

|

Kitchen |

|

|

|

|

Lounge |

|

|

|

|

Bedrooms |

|

|

|

|

Garden |

|

|

|

|

Ceilings |

|

|

|

|

Commercial Spaces |

|

|

|

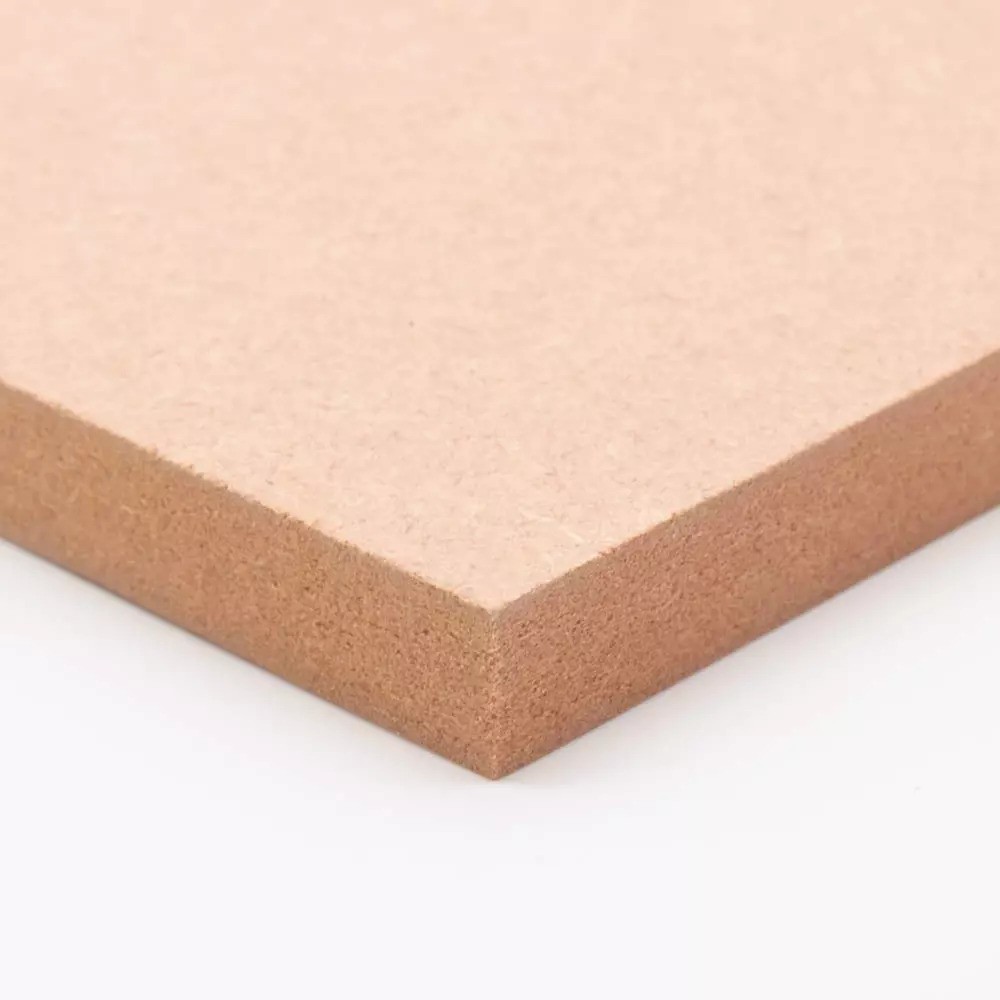

Standard MDF

Standard MDF is the most common type used for DIY and construction projects. It has a consistent light tan colour and a smooth, sanded surface. Standard MDF provides an affordable, versatile option suitable for a wide variety of applications.

- Density and Weight: Standard MDF has a uniform dense structure with a density of 700-800 kg/m3. A 2440 x 1220 x 18mm sheet weighs approximately 36kg.

- Strength: The consistent density throughout standard MDF panels gives them good bending strength and resistance to impacts and shocks. Standard MDF can be used to make structural components.

- Machining: Standard MDF cuts cleanly with carbide-tipped blades and can be reliably shaped with standard woodworking tools, however, it may dull cutters slightly faster than natural wood. For best results, pre-drill holes before screwing or use self-tapping screws.

- Finishing: Standard MDF takes primer, paint and varnish very well. The edges are porous so should be properly sealed when painting. It is an ideal material for painted furniture and cabinetry. These sheets can also be laminated or veneered to create a decorative surface.

- Moisture Resistance: Standard MDF will expand and structurally degrade over time with prolonged exposure to significant moisture. As such, it should not be used in wet environments like bathrooms without proper sealing.

- Applications: Widely used for furniture, cabinets, shelving, door frames, architraves, storage and display units.

- Cost: Typically, this MDF offers the most affordable option.

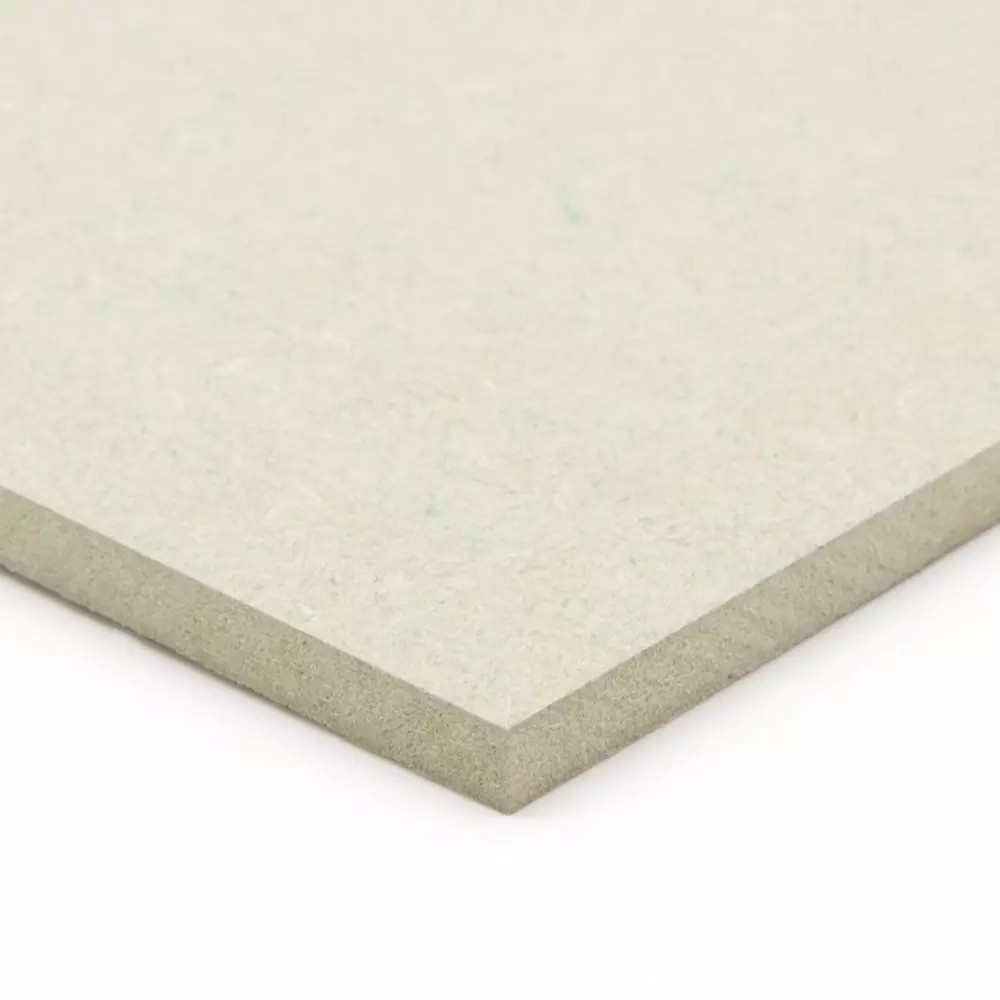

Moisture Resistant MDF

MR MDF is treated during the manufacturing process to create greater water repellency and resistance to humidity and dampness. The wood fibres in MR MDF are coated with hydrophobic wax and resin which inhibits swelling and structural breakdown.

The properties associated with moisture-resistant MDF make it ideal for applications in environments such as kitchens or bathrooms, for example as an alternative to wood wall panels, where humidity and moisture levels are higher and may damage real wood. It can be used for utility rooms and laundry rooms, as well as boiler rooms, cubicles and washrooms in commercial settings.

- Density and Weight: MR MDF has a density of around 720 - 750kg/m3. A 2440 x 1220 x 18mm sheet weighs approximately 39kg.

- Strength: Similar to standard MDF, MR MDF provides sturdy construction and good fastening strength for hinges and hardware.

- Machining: It cuts, drills, shapes and finishes the same as standard MDF. It glues well and takes finishes nicely.

- Moisture Resistance: As the name suggests, MR MDF can withstand higher levels of humidity and short-term water exposure without swelling or losing structural integrity. It offers increased dimensional stability in damp environments when compared to standard MDF. The edges should still be sealed where very prolonged dampness is expected.

- Cost: MR MDF costs up to 50% more than standard MDF due to the special moisture-resistant treatment

- Applications: MR MDF is ideal for bathroom vanities, kitchen cabinet doors and carcasses, laundry shelving, and other projects where moisture resistance is critically needed.

Flame Retardant MDF

In those instances where safety is paramount, fire-retardant (FR) MDF can provide up to an hour of fire protection. FR MDF is manufactured to meet strict fire safety standards and codes required for commercial, public and multi-occupancy residential buildings. The panels are impregnated during production with chemical additives that inhibit ignition and slow the spread of flames.

Commonly used in schools, hospitals, offices or cinemas, our flame-retardant MDF boards provide the best support when used in applications such as doors, kick plates or partitions. Flame retardant MDF has a pale red tint in its appearance, though it takes well to paints and primers.

Please note, that to prevent affecting the Flame Retardant properties, an appropriate flameproofing paint should be used. If you are in doubt, please consult a qualified engineer or architect.

-

Density and Weight: Fire retardant MDF has a density of approximately 750kg/m3. A 2440 x 1220 x 18mm sheet weighs around 39kg.

-

Strength: Comparable to standard MDF, fire retardant MDF provides sturdy construction for furniture and fixtures.

-

Machining: FR MDF cuts, drills, shapes and finishes the same as standard MDF.

-

Moisture Resistance: Similar to standard MDF, fire retardant MDF is not suitable for prolonged dampness. The edges should be properly sealed against moisture.

-

Fire Rating: Our fire-retardant MDF are class C panels, meaning they achieve a fire resistance performance of 30 minutes.

-

Cost: The special fire-inhibiting treatment increases the cost of FR MDF by up to 100% over standard MDF.

-

Applications: FR MDF is required for wall panelling, doors, cabinets, office furniture and displays in hotels, schools, hospitals, apartments, nursing homes and other high occupancy buildings where fire safety is paramount.

Choosing the Right MDF

When selecting MDF, consider the functional needs of your project in terms of required structural strength, workability, moisture resistance and budget.

|

Standard Grade |

Moisture Resistant |

Flame Retardant |

|

|

Paintable |

|||

|

Sandable |

|

||

|

Machineable |

|||

|

Flame Retardant |

|

|

|

|

Moisture Resistant |

|

|

|

|

Structural |

|

|

|

For most general DIY projects, standard MDF offers the best value for money. It's easy to work with using basic woodworking tools, accepts paint and varnish nicely, and provides a stable material for building furniture, cabinets, shelving units, trims and displays. Be sure to properly seal any cut edges to prevent swelling from moisture.

Moisture-resistant MDF is the ideal choice when the finished project will be exposed to significant humidity and dampness. It performs very well in kitchens, bathrooms, laundry rooms and other wet areas while maintaining the same great machining qualities as standard MDF. The added moisture resistance is worth the moderate extra cost for increased longevity.

Fire retardant MDF should be chosen when constructing projects that must comply with strict fire safety regulations. The flame retardant chemicals do increase the cost noticeably but are necessary to achieve certified fire resistance ratings. FR MDF is required by law for many public and commercial buildings.

All of our MDF is readily available in a wide range of sizes and thicknesses. We only stock MDF from trusted, reputable brands, including Medite, Kronospan or Egger.